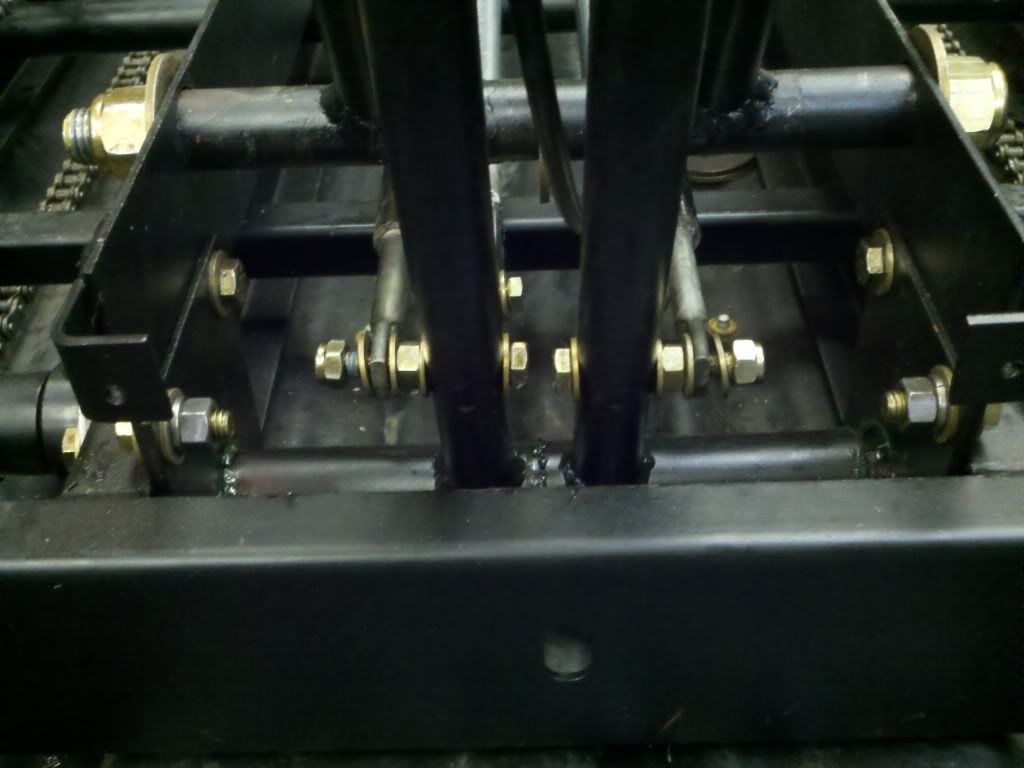

I decided to split the shifter since I was in there! and I want to soap the floor and spin donuts till I throw up!

guessed at the angle.

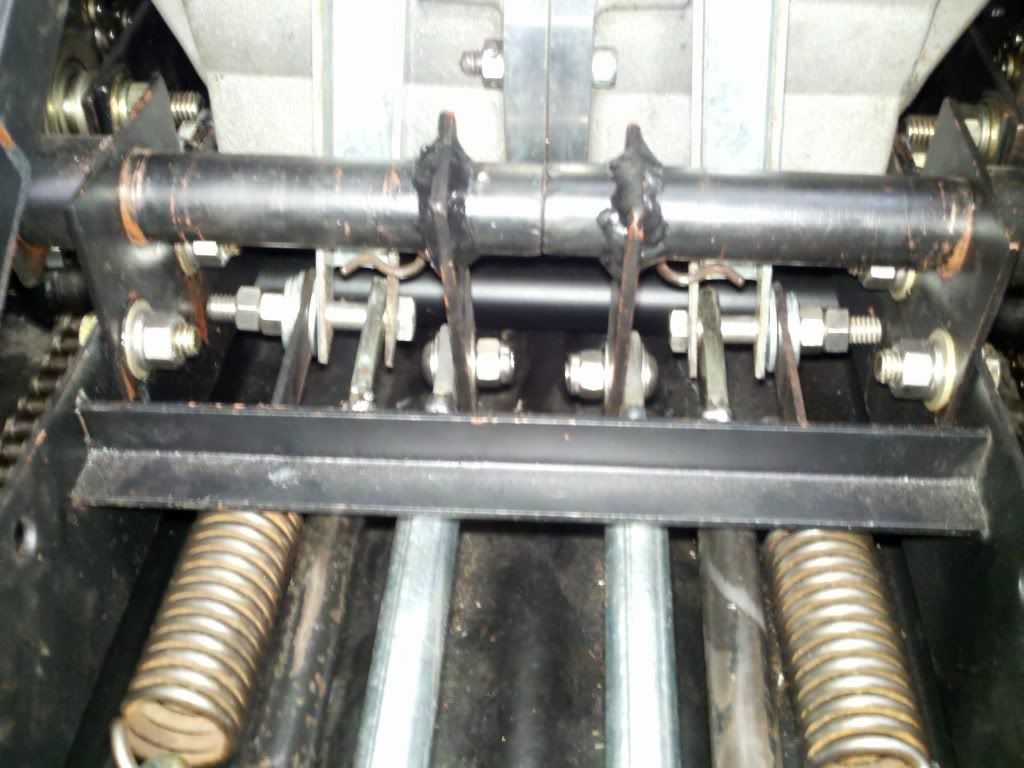

3/4" all thread fits real nice inside the tubing.

I am definitely going to change some stuff up, the steering rods need to be shimmed outward and Im going to have to shim the shifters inward.. I have a plan for tomorrow..

Reply With Quote

Reply With Quote

And sounds like fun, Just get it on video

And sounds like fun, Just get it on video

My Runner

My Runner