While you have the frame out and the brain juices flowing.. Reinforce the T-20 mount. Hustlers are notorious for the T-20 to come loose at the worst possible time. There are several pictures of how members have reinforced their T-20s. Browse the gallery and rebuild threads for ideas.

Announcement

Collapse

No announcement yet.

My Hustler rebuild (with a few tasteful modifications/upgrades) :D

Collapse

X

-

Split Shift Part 2 (Back)

Dan, I'm with you... I did just that, right about the same time that I did the split-shift mod. I'll post some pics.

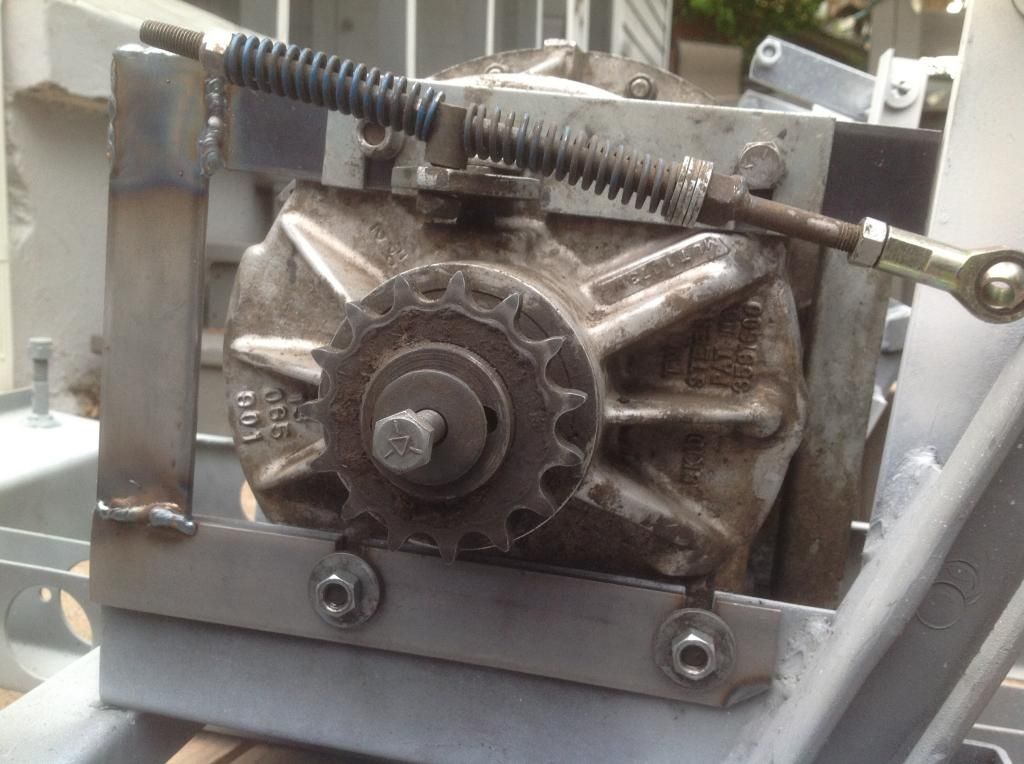

Now, on to the back half of the split shift set up. First you have to decide where and how you are going to install your new inside (driver's side) support for the round bar running parallel across front of the T20. As you can see here, I chose to go down to the bottom of the transmission mount box, using the leading edge of the vertical portion to strengthen the support. There are no doubt, several ways of doing this, just make sure that your T20 U channels can move freely, without interference. Now, its just a question of cutting the round bar where you know you still a bit of bar sticking through, once you thread it through your support (you are going to weld a heavy washer as retainer on the end of this numb). Cut the other side of the bar any place after its stock retention washer. Drill your carrier hole to match the size of the round bar so that it turns freely, but has no additional room. Thread the round bar through your drilled support hole, and then weld your support to your chosen point of attachment.

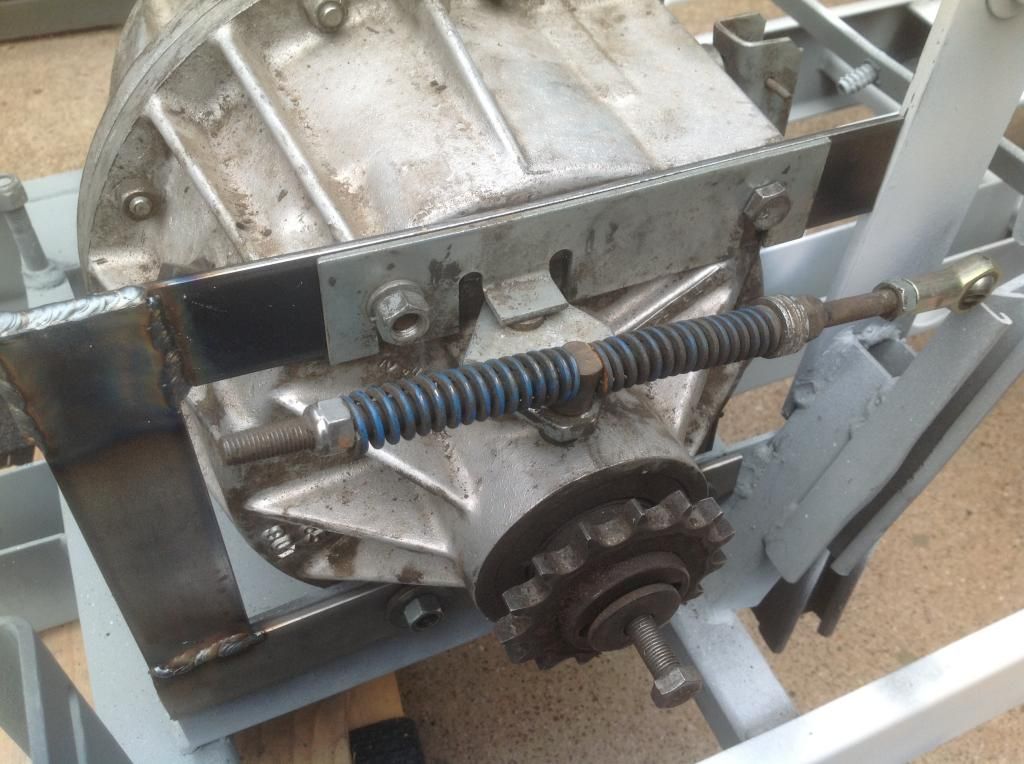

At this point, move to the passenger side. You are going to make an inverted "U" off of the top of the stock round bar support, that will extend outward and then come down to carry and support the very end of the round bar. Find some heavy, I think I used 1/8th in flat bar steel and measure a piece that will extend outward until it well clears the shift arm. Cut that piece to size and then weld in place.

From there, you take your flat bar stock and measure a piece that will drop down forming the other leg of the inverted "U" far enough to carry the round par once it's drilled out. Cut that piece, drill it out, thread it on the bar and then weld up. Now would also be a good time to cut the weld on the shift arm bolt and replace the bolt with a longer one, as the bolt will now be carrying the width of two heim joints instead of one. It should all look something like this...

Comment

-

T20 Mount Reinforcement

This is how I braced my T20 to withstand the greater twist factor associated with the split shift. Nothing to fancy, just 1/8" flat bar with notches and holes to match up with the stock mounting studs, and another notch to clear the shifter ears.

Painted

Comment

-

Damn fine work...love it..keep it coming and thanks for sharing...MUSCATEER 6x6

Kubota 14hp 2cyl diesel engine, Hagen/Rooter transmission Comet 780 Drive/770 Driven 22x12x8 Bearclaw tyres

Soon to add on a ... RHB31 Turbo..guess that would make it a

MUSCA TUR BOTA then eh?

MUSCA TUR BOTA then eh?

94 F350 4x4 7.3 IDI ZF 5sp

90 Bronco..awaiting a rebuild like no other = Tons and turbo diesel

Okanagan Similkameen BC Canada

Al "Camo pants"

Comment

Comment