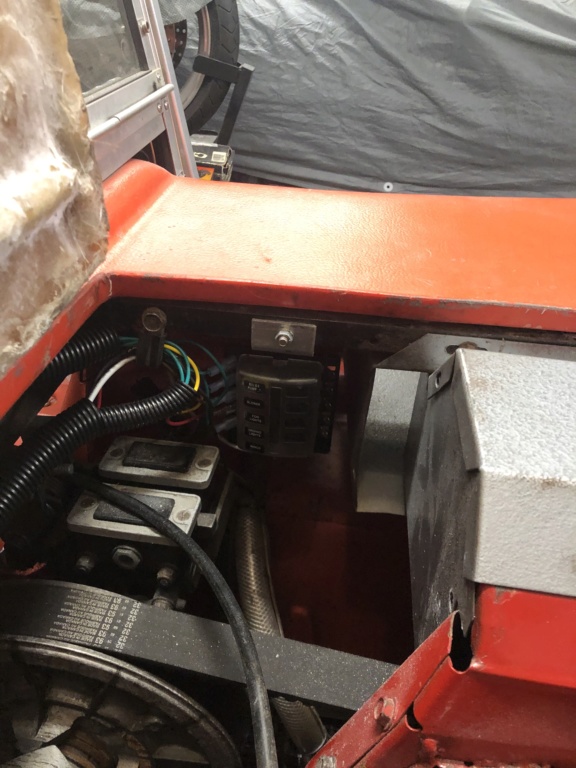

Working on the firewall:

I was planning to a completely new firewall out of diamond plate aluminum, but I think I'm going to do a combination of the original firewall and aluminum pieces.

Basically, I decided I don't want aluminum edges rubbing against the plastic tub walls and possibly wearing them away or thinning them over time.

I was planning to a completely new firewall out of diamond plate aluminum, but I think I'm going to do a combination of the original firewall and aluminum pieces.

Basically, I decided I don't want aluminum edges rubbing against the plastic tub walls and possibly wearing them away or thinning them over time.

Comment